DAF Unit

The best solution for cleaning wastewater from suspended solids including fats,oil products,and phosphates while reducing COD and BOD in wastewater.

Description

The DAF-unit is the best solution for cleaning wastewater from suspended solids including fats,oil products,and phosphates while reducing COD and BOD in wastewater.

Scope of application of DAF-Units:

Esmil Dissolved Air Flotation systems(DAF)are used for the treatment of wastewater in various industrial facilities:

food industry(meat,dairy,fish,canning,etc.),

textile and leather,

oil and fat plants,

iron and steel industry,

Sludge thickening

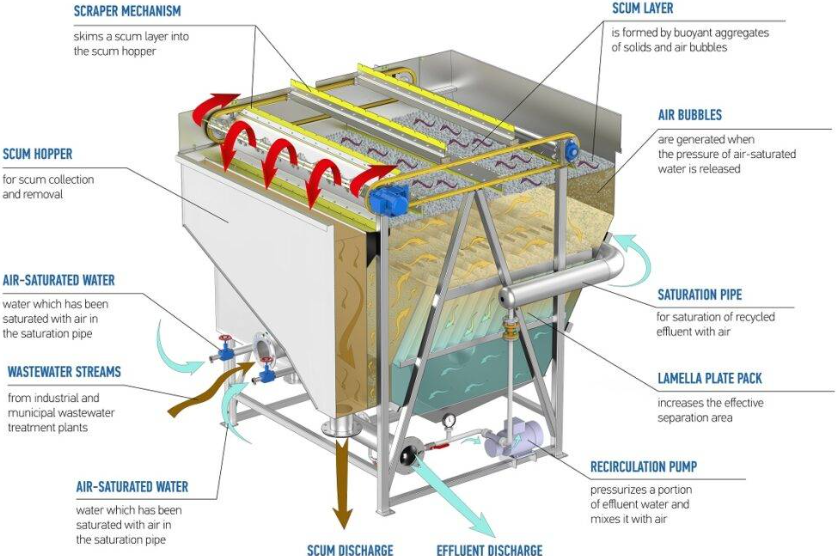

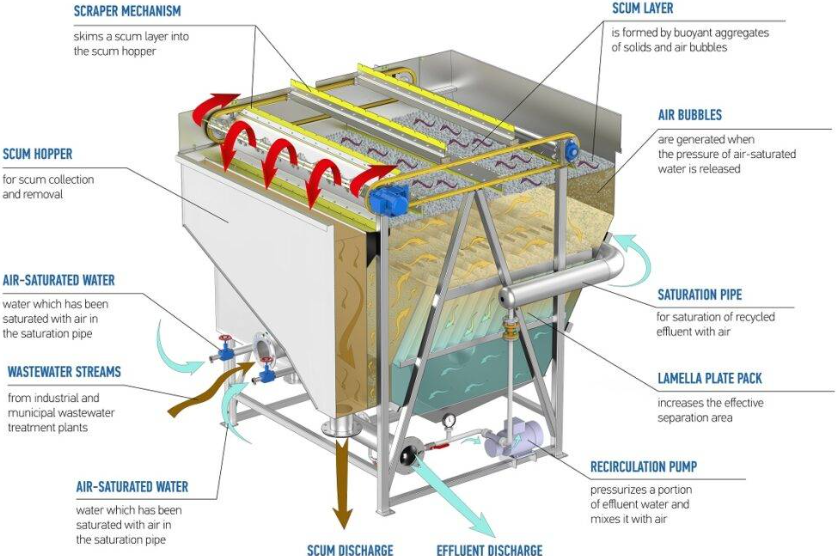

Operational principle of DAF-Units

The initial wastewater is pumped to the mixer inlet,i.e.to the DAF-unit,where the effluents are treated with reagents and then enter the mixing chamber with the simultaneous supply of a water-air mixture.Air and suspended solids float to the surface in the form of coagulated particles.Larger flotation complexes reach the surface at the mixing chamber stage.The rest goes with the wastewater to the flotation chamber.The resulting foam is removed from the surface of the water by the scraper mechanism and discharged into the collection tray.Heavy contaminants settle on the bottom of the unit and are removed.The clarified wastewater is discharged from the installation.Part of the purified water is taken by the pump to saturate it with air.After this,the air-water mixture enters with the mainstream into the mixing chamber of the flotator.The water level in the flotator is controlled by changing the overflow height.

Advantages of DAF-Unit

The dissolved Air Flotation system(DAF)is designed for each specific case and the equipment can adapt to any environmental setting.

The type,size and shape of the containment as well as the internal construction of the DAF-unit are selected for each specific case and designed using(CAD)computer-aided design.

The cone shape bottom provides high-quality of sediments removal.

The synchronized patented scraper mechanism minimizes,the destruction of floating sludge during its movement on the surface of the water.

Lamellas specialized form of corrugated plates and individual sizing of the desired distance between the shelves makes using a thin-layer module as efficient as possible in each particular case.

Specially designed,patented mixers efficiently mix reagent solutions with effluents.

The complex system is controlled from the(HMI)human machine interface screen or other devices through remote access.The control cabinet is constructed using Siemens PLC and Schneider Electric components.

Benefits of using DAF-Unit

Effective separation of oil products,suspended solids,and fats help to increase performance and treatment quality.

Preparation of the wastewater facilities for discharge into the city networks.

Eliminating the risk of additional costs for exceeding the permissible wastewater indicators.

Elimination of problems concerning pipeline clogging and wear of other related equipment.

The unique design of the scraper mechanism allows changing the rotational speed of the drive,and the number of scrapers in cases where a large amount of floating sludge and foam is formed.

Efficiency of DAF-Unit(quality of treatment)

| Industry | COD | Suspended solids | Oil products and fats | Phosphates | Sulphides | Metals |

| Slaughter and meat processing | 55-80% | Up to 98% | Up to 95% | Up to 90% | Up to 99% | Up to 95% |

| Dairy industry | 35-60% | Up to 98% | Up to 95% | Up to 90% | Up to 99% | Up to 95% |

| Oil refining | 45-55% | Up to 95% |

| Up to 90% | Up to 99% | Up to 95% |

| Other industries | 35-80% | 85-95% | 85-95% | Up to 90% | Up to 99% | Up to 95% |

Durability of DAF-Units

The self-cleansing system of the thin-layer modules extends the period of routine cleaning of equipment.

The elements of the scrapers are made of polyurethane,which guarantees a long service life.The use of special elastomeric materials guarantee resistance to specific effluents.

The tank is made of AISI 304stainless steel,optionally AISI 316or fibre-reinforced polymer(FRP).

Optional outfitting of DAF-Units

ventilation duct;

explosion-proof construction;

antifoaming devices in a collection tank;

saturation system;

design to transfer the DAF-unit data to the upper-level control system using standard communication protocols;

design of automatic integration with mechanical cleaning units,tanks,conveyors as well as dewatering systems.

Characteristics

Technical characteristics of DAF-Unit

| Productivity,m3/h | 2-280 |

| Recirculation coefficient,% | 20-200 |

| Recycle pressure,bar | 5-6.5 |

| Flotation surface,m2 | 0.5-21.6 |

| Lamella block volume,m3 | 0.5-16 |

| Reduced lamella block flotation area,m2 | 5-94 |

Sewage Treatment Equipment Rotary Drumfilter